Our TPC

What is TPC

Teak Polymer Composite or in short TPC is a composite material that is the result of combining teak dust, polymers, and a set of additives. This essentially makes TPC a subcategory of the broader stated Wood Plastic Composite (WPC). The high density of the material gives it very little water absorption, besides of course the increased strength, which makes it perfect for outdoor applications. At Destination Green we tend to focus on the production of decking related products, door and window frames, boat decking, bathroom furniture, furniture components and many more.

Why our TPC

The two decisive factors to make a TPC product of high quality are: The quality of the basic raw ingredients and secondly the using of these ingredients in the right proportions. At Destination Green we do both to ensure that our TPC is always of the utmost quality. Teak dust is the primary ingredient in our TPC, we source this material from local Furniture Manufacturers who cannot use it themselves, making their “waste” our main ingredient. Besides Teak dust being a recycled ingredient it also enhances the natural look we try to achieve in our composite.

Why we produce TPC?

By using recycled A grade HDPE, we can achieve a WPC product which is not only made of 90% recycled material yet is also 100% recyclable. We mainly use WPC as is in our belief it is a far more environmentally friendly material than natural wood. The wood component in our WPC is a left over from the already existing wood manufacturing of furniture; therefore no trees will be cut for the production process of our TPC. Secondly our TPC is far better prepared to withstand the test of time, as it requires little maintenance does not crack, has almost no water absorption and has very little discoloring.

Experience

We started our production of TPC in 2012. After numerous improvements, it is now safe to say we have a product that is excellent in both quality and appearance. In 2018 we started a new cooperation with Resindo in Tangerang, Resindo is a 50/50 joint venture between The Compound Company, a Dutch company specialized in compounding and PT Polymindo Permata, a premier provider of high-end all-weather wicker synthetic fibers more commonly known as Viro. Consequently this resulted in a new company; PT. Teak Polymer Composites. In 2018 we received the DAME award in the prestigious METS boat fair for our new innovated teak polymer boat decking.

Location

Since April 2019 our main production is in Tangerang, Banten. Here we do the mixing, compounding and extrusion. Furthermore, we also have a professional laboratory to test our products. Besides our facility in Tangerang we also have another facility in Bantul, Yogyakarta. Here we specialize in making the teak pellets used in our composite and the assembly of our furniture. Last but not least we are also active in The Netherlands where we focus on developing composites for new markets and applications.

Process

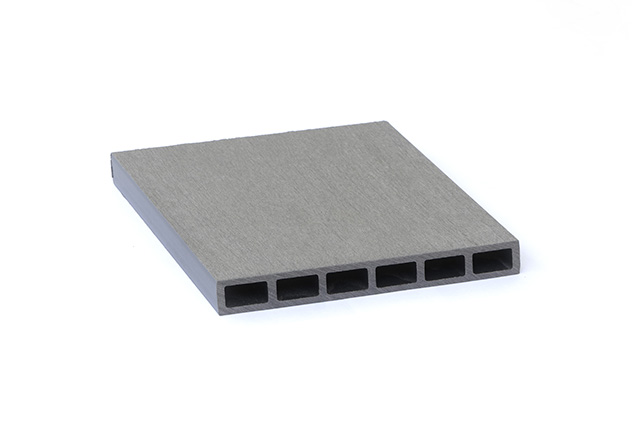

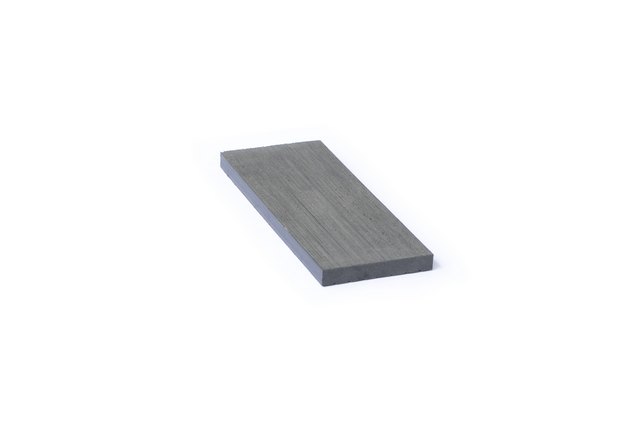

Although we are exploring various applications for injection molding and 3D printing most of our current product offering is extruded. Extrusion essentially means that we push the TPC materials through a mold, also known as a die that has a certain profile or shape under high heat and pressure. This process results in a TPC “plank” that follows aforementioned profile. The plank that results from this process can be made in any length. Some profiles are fairly complicated and have various hollow spaces; others are more simple and solid. An example of some of our WPC profiles is depicted below.

Decking Small Grooves

Door/Window Frame

Flat Thin

Flat Hollow

Table Top

197 x 25 mm

Decking 8 Groove

Window Frame

Flat Thick

Wall Cladding

Decking 7 Groove

Beam Large

Flat Small

Fence

200 x 29 mm

Decking Flat

Beam Small

Flat Small Grooved

Fluted Wall Cladding

140 x 30 mm